The Customer

Ostbayerische Technische Hochschule Regensburg university (OTH Regensburg) was founded in 1971 as a university for technology, economics and social affairs. Today it is one of the largest universities for applied sciences in Bavaria. With 10,000 students the University has a range of faculties including Civil and Mechanical Engineering. In the Building Materials Technology Department at OTH Regensburg a double-walled strong floor facility was planned and built with a view to using this initially for earthquake simulation. Professor Dr. Detleff Schermer describes the project.

Ostbayerische Technische Hochschule Regensburg university (OTH Regensburg) was founded in 1971 as a university for technology, economics and social affairs. Today it is one of the largest universities for applied sciences in Bavaria. With 10,000 students the University has a range of faculties including Civil and Mechanical Engineering. In the Building Materials Technology Department at OTH Regensburg a double-walled strong floor facility was planned and built with a view to using this initially for earthquake simulation. Professor Dr. Detleff Schermer describes the project.

|

The Challenge

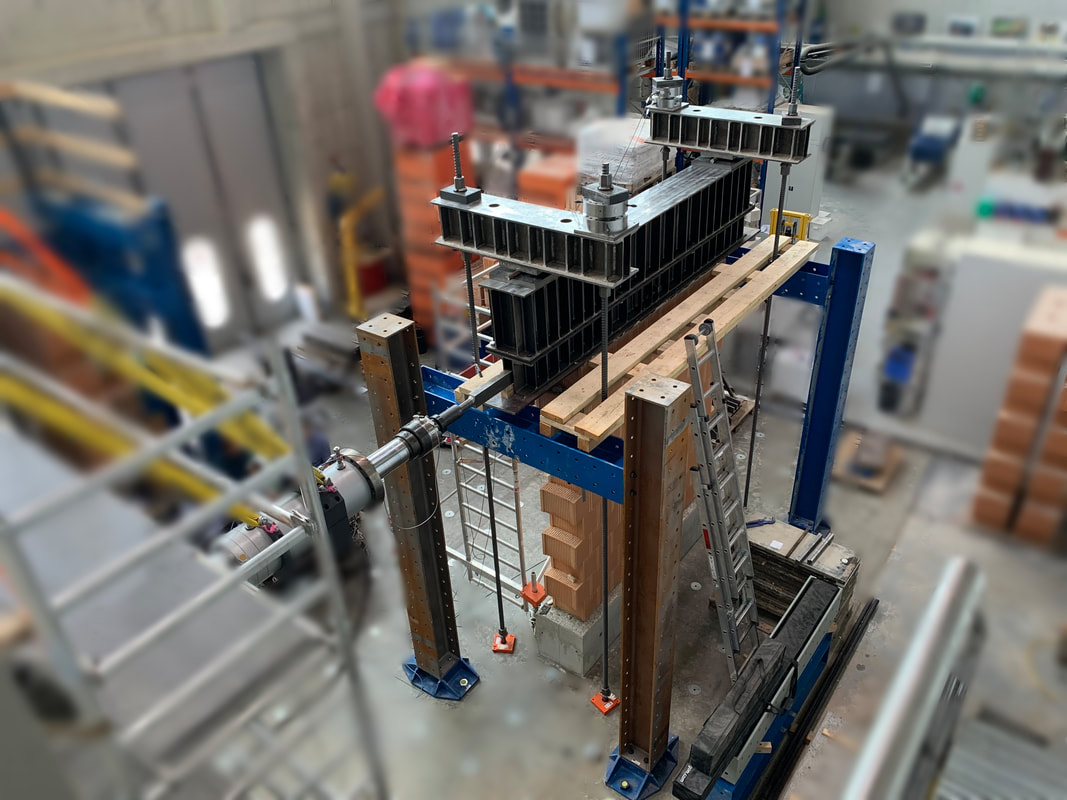

A wall, usually made of masonry, is prestressed vertically over two axes and then loaded horizontally with a shear axis. The challenge was to find a system that could effectively control multiple, interdependent axes of control. The Solution An individual masonry wall was built by hand on the strong floor and finished at the top with a steel load distribution beam. This wall was loaded individually on the left and right with actuators controlled by two Control Cubes. Depending on these two axes, nominal values for the horizontal shear movement of the wall were calculated in the test and transferred to the third load axis in the current test. The test setup supplied consists of four tie-bar cylinders with a nominal load of 1000 kN, as well as a double-acting synchronized cylinder with a nominal load of 500 kN. |

The system also currently includes two hydraulic pumps (three in the final stage), each with a nominal capacity of 15 l/min. For control, 3 Control Cube Systems from CATS³ Limited were used and the pump hardware and project management were implemented by Toni Technik.

The test setup is used for testing masonry structures in building construction and is an important building block for planning and erection of individual, i.e. stone-built, building construction projects.

Benefits

This force application technology in conjunction with the universal strong floor on site at the customer's premises, combining sophisticated control strategy on the Control Cube, makes very complex testing tasks possible. The Cube can be transferred or reused in different configurations (e.g. from a dual channel test rig to a three channel test rig) – this makes it a flexible and cost effective solution.

“The new building has enabled the department to address topics such as earthquake simulation testing of masonry - which is a very important topic worldwide.” Prof. Dr. Detleff Schermer

The test setup is used for testing masonry structures in building construction and is an important building block for planning and erection of individual, i.e. stone-built, building construction projects.

Benefits

This force application technology in conjunction with the universal strong floor on site at the customer's premises, combining sophisticated control strategy on the Control Cube, makes very complex testing tasks possible. The Cube can be transferred or reused in different configurations (e.g. from a dual channel test rig to a three channel test rig) – this makes it a flexible and cost effective solution.

“The new building has enabled the department to address topics such as earthquake simulation testing of masonry - which is a very important topic worldwide.” Prof. Dr. Detleff Schermer